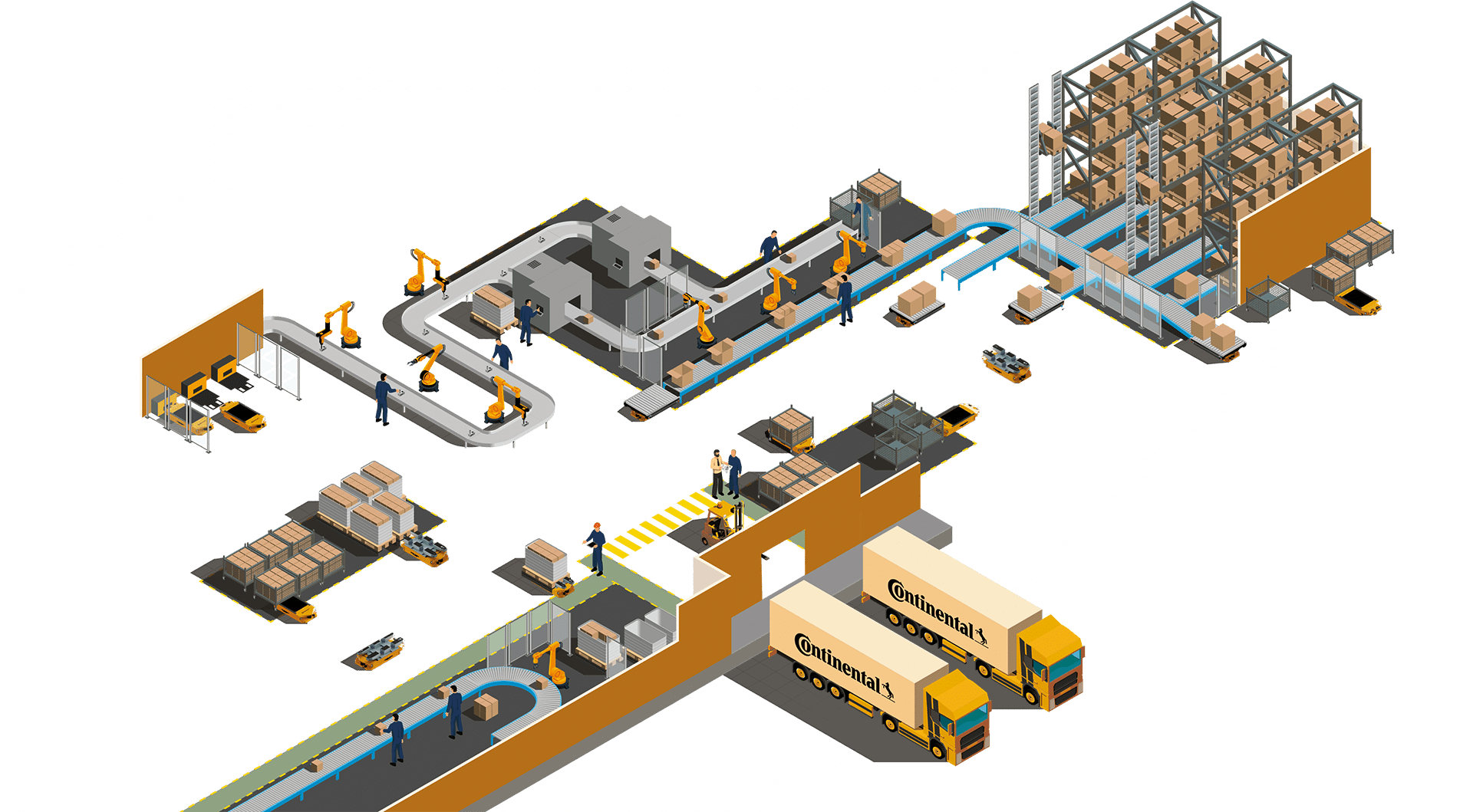

A robot by itself won’t master your challenges. But when it’s fully integrated, the sky is the limit. Learn how to make the most of your intralogistics with autonomous material flows, smart Fleet Master Control software, and end-to-end 24 / 7 support.

Get proactive support in every stage, from planning across implementation to maintenance.

Enjoy knowing that you can integrate all your processes in a matter of days – without disrupting ongoing operations.

Maximize efficiency by tapping your fleet’s full performance potential and slashing costs at the same time.

Maximize safety for people at your site and using your products while ensuring reliable material flows.

Count on a power-packed unit for effortlessly lifting items that weigh up to 1200 kg.

Stay in charge with our Fleet Master Control software. Benefit from a smart charging strategy and remote diagnostics.

Attention to details.

Our relationships with customers are sustainable and trust-based. Although our products are technical, our personal interactions add essential value.

Some things require more tailored attention than a conventional warehouse can deliver. Expand the range of possible applications with changes that are precisely matched to recurring intralogistical processes.

Maximum payload: 600 kg | 1200 kg

Top roller modules from our partner ROEQ

Maximum payload: 600 kg | 1200 kg

Maximum payload: 300 kg

For transporting small load carriers

Use case: Small load carrier, half pallets

Our intelligent, user-friendly Fleet Master Control software is the AMR solution’s core. The intuitive user interface makes it easy to add and customize routes. Maps and dashboards help you consistently track your AMR fleet, shipping runs, and battery charging operations in real time.

Ensuring interoperability between different robotic systems with a best fit approach of each robot. Seamless integration of the AMR's into robot fleets of the customer to enable the full performance using one single platform. Maximizing operational excellence by partnerships with the following Fleet Management operators:

Fleet Master Control

The Fleet Master Control has the main task of integrating the Autonomous Mobile Robots (AMR) into the operational environment and coordinating their transport orders. This includes transport order management, which triggers orders and ensures they are fulfilled. Vehicle dispatching selects the most appropriate vehicle for the job, based on various criteria such as travel distance or battery status. The fleet manager also monitors the charging status of the vehicles and guides them to the charging station depending on the charging strategy. In addition, the Fleet Master Control acts as a traffic controller to set rules for the operation of the fleet. Likewise, it is responsible for route planning to find the optimal driving route for each transport job. The intuitive user interface makes it easy to add and customize routes. By processing all relevant information, the fleet manager ensures that transport orders run smoothly. The AMR fleet orders can be tracked in real time at any time using maps and dashboards.

Dimensions |

Length × width × height |

1,455 mm × 630 mm × 225 mm |

Performance Characteristics |

Rotation diameters |

260 cm |

Power Supply |

Battery type |

Li-Ion / 48 V / 47 Ah |

Environment |

Ambient temperature |

5°C – 40°C |

Safety |

Sensors and safety functions |

4 × LIDAR Laser Scanner, 2 × 3D camera, |

Connections |

Wi-Fi link |

2.4 GHz and 5 GHz supported, 2 antennas |

Length × width × height

Weight

Ground clearance

1,455 mm × 630 mm × 225 mm

240 kg

28 mm

Rotation diameters

Navigation

Position accuracy

260 cm

Autonomous

Fine positioning: ± 5 mm

Battery type

Charging current

Loading strategy

Loading time

Li-Ion / 48 V / 47 Ah

25 A / max. 30 A

Opportunity Charging

1:20 h

Ambient temperature

Humidity

5°C – 40°C

10 % – 90 % @ 39°C, noncondensing

Sensors and safety functions

Detection range

Safety standards for Industrial Vehicles

IP Code

4 × LIDAR Laser Scanner, 2 × 3D camera,

4 × emergency stop button, 2 × red light, optional: signal tower

360°

MRL 2006 / 42 / EG, EMV RL 2014 / 30 / EU, RED RL 2014 / 53 / EU,

EN ISO 13849-1:2015, EN ISO 13849-2:2012, EN 1175:2020, CE,

ISO 3691-4:2020

IP20

Wi-Fi link

Ultra-wideband (UWB) ready

Integration

Manual control

2.4 GHz and 5 GHz supported, 2 antennas

Yes

VDA 5050 compatible

USB controller, control via laptop computer or mobile phone

Our AMRs keep your processes running smoothly and reliably. And if there’s ever a need, you can count on us: we’re available 24 / 7 to provide assistance and support.

We work with you to identify the areas and processes that can benefit from automation with our AMR.

We install the AMR and get it up and running, then teach you to confidently manage the Fleet Master Control system on your own.

Processes, goods, and materials can change. We’re available to optimize your AMRs performance whenever there’s a need.